Wastewater treatment

Clean water is a crucial commodity. However, the availability of clean water is in the increasing jeopardy with the progression of industrialization (especially in the developing countries) and the effective wastewater remediation becomes more and more essential.

The problem is enhanced by the fact that many chemical or pharmaceutical plants produce more and more chemicals which are not only toxic and should not be dumped into the global water resources, but they are also chemically stubborn and resistant to typical wastewater treatments. The main problem of these pollutants is their resistance to oxidative reactions i.e their high reduction potential. Degradation of these chemicals (such as aromatic compounds, phenols, benzene, toluene, azo-molecules etc.) requires oxidative agents having a very high oxidation potential in order to be effective. An extreme example of such toxic and difficult to degrade wastewater types are the hydrraulic fracking liquids and their leachate [Ref.source].

| Species | Oxidation potential [V] |

|---|---|

| Fluorine | 3.03 |

| Hydroxyl Radical | 2.80 |

| Atomic Oxygen | 2.42 |

| Ozone | 2.07 |

| Hydrogen Peroxide | 1.78 |

| Permanganate | 1.68 |

| Chlorine Dioxide | 1,58 |

| Chlorine | 1.36 |

| Oxygen molecule | 1.26 |

| Ref. source |

The oxidation potentials of various oxidation agents are listed in the table. The list shows a wide range of potential values for common oxidizers. Hydroxyl radical is at the top of the list, surpassing by far the atomic oxygen species, ozone and other common agents. It is clear from the table that for example ozone is not capable of oxidizing molecules that have their potential higher than 2.07 V, such as aromatic rings, e.g. benzene or toluene, for which Eo values in a solvent equal respectively to 2.48 and 2.26 V [ref.source]. For this reason, such aromatic rings can actually only quench ozone and they cannot undergo remediation by ozonation methods. By contrast, these aromatic rings are accessible for oxidation by the hydroxyl radical.

In practice, there are myriads of stubborn pollutants in the wastewater that fall into the gap between the hydroxyl radical potential and the rest of the oxidative agents, especially from the difficult pharmaceutical or chemical industries, including antibiotics, pesticides, herbicides, leachates. For such cases, Advanced Oxidation with the use of hydroxyl radicals is the only available remedy.

Catalytic Advanced Oxidation with hydrogen peroxide

Hydrogen peroxide is an ideal tool for water purification, because it does not introduce any harmful chemicals such as bleach or chlorine and decomposes into water and oxygen, according to the reaction:

2 H2O2 → 2 H2O + O2

While hydrogen peroxide is a useful oxidant - as shown in the table of oxidation potential - the introduction of a specialized catalyst (OXYCATALYST) moves the reaction to the top of the table, because the catalyzed reaction produces Hydroxyl Radicals as the oxidative species. Hydroxyl radicals are therefore much more powerful than the hydrogen peroxide alone.

Read more: Hydroxyl Radicals Reactivity

Catalytic decomposition of hydrogen peroxide can be also evaluated with Methylene Blue, which is the known indicator of hydroxyl radicals. In the presence of hydroxyl radicals Methylene Blue undergoes decoloration, even in hydrogen peroxide environment which is not a reducing agent. The decoloration of Methylene Blue is instant and fully accomplished within minutes when treated by catalyzed hydrogen peroxide.

Wastewater treatment

Catalyzed decomposition of H2O2 results in the abundant formation of hydroxyl radicals which are extremely powerful in oxidation reactions. The hydroxyl radicals are fast and efficient in elimination of all types of pollutants: organic matter, toxic chemicals, pharmaceutical waste, agricultural waste, fertilizers, herbicides, antibiotics, dyes (including azo dyes), fracking waste and so on. Wastewater treatment reduces COD (Chemical Oxygen Demand) and BOD (Biological Oxygen Demand). COD is a measure of organic pollution in water and BOD is a measure of the oxygen used by microorganisms to decompose this waste.

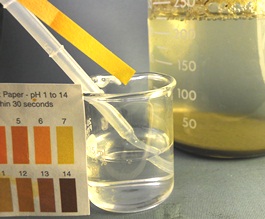

The Catalytic Advanced Oxidation process cleans and disinfects water without introducing any harsh chemicals and does not affect solution pH (unlike Fenton reagents). The catalyst is heterogeneous, which means that it will not be dissolved in water and can be removed and reused. Hydroxyl radicals are very short-lived (of the order of nanoseconds) and therefore they do not remain in the effluent after treatment - their excess is annihilated as oxygen gas generation. Catalytic Advanced Oxidation reduces organic pollutants and toxic chemicals, eliminates odors and colors, sterilizes and disinfects effluents by attacking pathogenic microorganisms and bacteria.

Dye Decoloration and Degradation by Catalytic Advanced Oxidation

Catalyzed decomposition of hydrogen peroxide allows effective decoloration treatment of dye wastewater. Our technology allows to fully degrade all kinds of industrial dyes, such as those commonly used in the food and textile industry (including the most notorious azo dyes) even in high concentration. The technology is environmentally friendly and does not use any harsh solutions or reagents such as chlorine, or any kind of bleach, strong alkaline or acidic solutions. No pH adjustment is needed for the treatment.

The process, which is based on the most efficient hydroxyl radicals, is much more powerful than any of the conventional methods. Our technology is able to fully remove color contaminants of such dyes as: Tartrazine, Erythrosine, Allura Red (red 40), Orange II, Bengal Rose, Fast Green, Brilliant Blue, Brilliant Green, Methyl Violet, Naphthol Yellow S, Erioglaucine, Rhodamine, Congo Red and other dyes. The technology is scalable and can be also used to treat other organic impurities.

Read more: Organic Matter Degradation, Dye Decoloration and Degradation, Catalytic Advanced Oxidation, Hydroxyl Radicals Reactivity, Oxycatalyst

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Oxycatalyst advantages - summary

- Oxycatalyst is uniquely capable of generation of an abundant amounts of highly active species - hydroxyl radicals OH· that exhibit unsurpassed oxidative capability

- no other chemicals or ingredients are needed than hydrogen peroxide H2O2 - the "cleanest chemical". Thus, no additional pollution is introduced by the treatment itself. This is in contrast to electrochemical AOP which introduce electrolytes or Fenton AOP which needs soluble iron salts, or flocculation

- Oxycatalyst is heterogeneous (i.e. in the solid state) and it is based on specific hetero-complex formed through nano-technology. Therefore it does not become part of the solution and can be recovered and reused multiple times

- Oxycatalyst enables easy adjustments of the kinetics of the reaction, depending on the requirements. There is a range of forms of the catalyst - from a fine powder to granulate of more than 5 mm, which can be used in various types of systems

- Oxycatalyst operates best at neutral pH = 7, but it can also be used in a wide range of pH - from alkaline to acidic. It does nor require pH adjustments (such as in the case of electrochemical methods and Fenton).

Crystallographic structure - Oxycatalyst is stable and controllable and does not deteriorate upon exposure to air or moisture or after prolonged storage

- Oxycatalyst can be stored indefinitely without any loss of their activity and structure, without protective atmosphere

- Oxycatalyst does not need activation or regeneration or any kind of preparation or reduction process

- Oxycatalyst has very high efficiency combined with low cost - it contains no noble or exotic elements. It contains no toxic or dangerous components

- Catalytic Advanced Oxidation does not require any external energy input and no expensive instrumentation.

- The method does not produce any sludge or unwanted byproducts, only very small amount of fully oxidized (mineralized sediment).

- Although the hydroxyl radicals are powerful and reactive, they do not survive in the application with hydrogen peroxide to become risky. The radicals are very short-lived and unstable, so they can either oxidize the chemicals in the effluent, or must instantly end up in oxygenmolecules, thus becoming the mn byproduct of Catalytic Advanced Oxidation, along with the water molecules

Read more: Oxycatalyst, Catalytic Advanced Oxidation

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Examplex of the degradation of pollutants

Heavily contaminated wastewater (with very high COD and BOD values) treated by Catalytic Advanced Oxidation with hydrogen peroxide.

ORGANIC MATTER WASTEWATER

Water Purification by Catalytic Advanced Oxidation with Hydrogen Peroxide

All types of organic matter (e.g. invasive or toxic algae, blue-green algal blooms, animal or human organic waste) can be remediated and sterilized by this reaction. The process finalizes in mineratization of the organic effluent with formation of a small amount of mineralized sedinemt, which can be easily separated. There is no need for introducing either acidic or alkaline change in pH. After the treatment and filtering off the sediment, clean, sterilized water with pH 7 is obtained. The processing achieves dramatic reduction of COD (Chemical Oxygen Demand) and BOD (Biological Oxygen Demand). COD is a measure of organic pollution in water, and therefore COD's allowable levels in the wastewater need to be achieved in wastewater.

DAIRY WASTEWATER

Treatment of organic dairy effluent by Catalytic Advanced Oxidation with hydrogen peroxide

ORGANIC MATTER WASTEWATER

Water disinfection and decontamination by advanced oxidation

Toxic chemical contaminants can be eliminated by the catalytic decomposition of hydrogen peroxide.

Phenol Degradation by Catalyzed Hydrogen Peroxide

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Read more

- Organic Matter Degradation

- Dye Decoloration and Degradation

- Catalytic Advanced Oxidation

- Hydroxyl Radicals Reactivity

- Cellulose Fibers Upgrading

- Oxygen Generation